ERP in manufacturing

How Data-Driven ERP Is Redefining Indian Manufacturing Competitiveness

- Highbar Technocrat

- Blogs

- December 15, 2025

Connect With Us

Beyond Automation: How Data-Driven ERP Is Redefining Indian Manufacturing Competitiveness

Walk into any modern Indian factory today — you’ll see machines whining, dashboards glowing, and operators tapping screens instead of punching numbers.

On the surface, it looks disciplined. But ask a plant head what keeps them awake at night, and you’ll hear the same chorus:

We have data all over, but very little insight

That single line captures the next frontier for Indian manufacturing.

Automation solved the how of production. But now, data-driven ERP systems are solving the ‘why’ and ‘what next’.

In a world where margins are thin, customers are demanding, and supply chains are fragile, data is no longer a by-product of operations — it’s the engine that drives competitiveness.

And for thousands of Indian manufacturers, ERP and SAP platforms are turning that raw data into strategic power.

India’s biotech manufacturing network is flourishing — yet below that optimism, many companies quietly wrestle with day-to-day inefficiencies.

1. Siloed systems and distributed data

Finance runs on one platform, inventory on another, and production data lives in spreadsheets. Teams chase information instead of insights.

2. Operational firefighting

Machine downtime, shipment delays, sudden demand spikes — most decisions are reactive, not predictive.

3. Lack of real-time visibility

Plant managers don’t always know which line is underperforming or which supplier will miss deadlines — until it’s too late.

4. Rising costs and compliance pressures.

Regulations are shrinking. Energy costs are shifting. And global buyers expect traceability and transparency.

It’s no surprise that many manufacturers feel they’re operating in the dark. And that’s precisely what data-driven ERP aims to change.

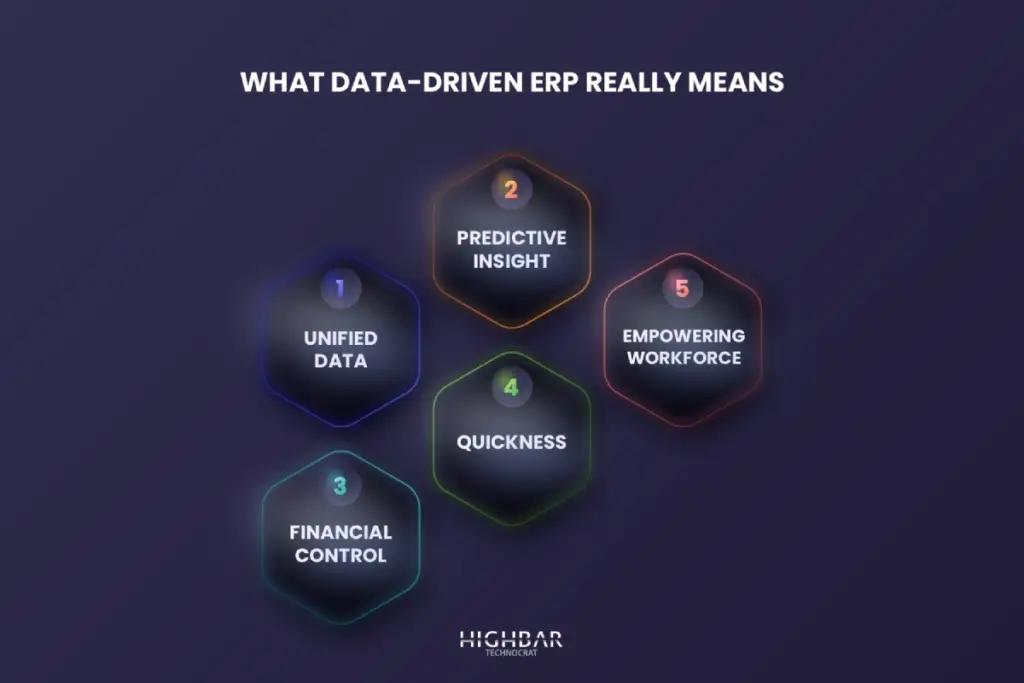

Beyond Automation: What Data-Driven ERP Really Means

When ERP first arrived in Indian manufacturing, it was mainly about automation — cutting manual work, restructuring processes, and reducing paperwork.

But the new generation of ERP, especially SAP S/4HANA and similar intelligent platforms, has evolved far beyond that.

Here’s what’s changed:

1. Unified Data = Unified Decisions

Instead of managing multiple systems, ERP generates a single digital spine for the business. Every division — from production to finance — works off the same, real-time data.

This means decision-makers don’t have to “guess” anymore. They know.

A production manager in Pune can see the same live inventory levels as the CFO in Mumbai — and both can forecast costs, capacity, and profitability instantly.

2. Predictive Insights Change Gut Feeling

With predictive analytics, ERP can flag possible breakdowns, material scarcities, or demand surges before they happen.

Envisage knowing which supplier will miss a shipment next week or which machine is about to be unsuccessful — and fixing it before disruption hits.

That’s the power of data-driven forethought. It’s like turning your ERP into an always-on business mentor.

3. Financial Control with Clarity

Traditional accounting tools show you what happened.

ERP shows you why it happened — connecting every rupee spent to an activity, project, or production.

CFOs get real-time profitability dashboards, making it easy to control costs, track project margins, and identify incompetence early.

4. Quickness for a Fast-Changing Market

Manufacturing no longer happens in isolation. Demand shifts overnight. Global supply chains affect local production.

ERP helps Indian manufacturers adapt quickly — scaling operations, switching product lines, and integrating new facilities without chaos.

5. Empowering the Workforce

The cleverest ERP systems now come with built-in, mobile-friendly dashboards. Workers can log quality checks, track work orders, or access performance insights right from the shop floor.

It’s not about replacing people — it’s about augmenting human capability with better data.

Real-World Examples: ERP in Action

Let’s bring this to life with real-world stories — because transformation isn’t just theory; it’s happening right now.

Case 1: A Pune-based Auto Component Supplier

This mid-sized supplier faced a familiar issue — massive data scattered across Excel sheets and disconnected software. Planning was guesswork.

After adopting an SAP-based ERP solution, they achieved:

- 30% improvement in inventory turnover

- 25% faster order fulfilment

- Significant drop in production delays

What changed wasn’t just process automation — it was the company’s ability to make decisions based on truth, not assumption.

Case 2: A Global Electronics Manufacturer Operating in India

This multinational used a cloud ERP system to unify its India and Southeast Asia operations. The outcome?

- 40% fewer supply chain bottlenecks

- Streamlined compliance with export documentation

- Improved collaboration across five countries

When every facility could see real-time performance data, decisions became faster — and customers noticed the difference.

The Bigger Picture: India’s Competitive Edge

The next decade of Indian manufacturing will be defined not by how cheap we can produce — but by how intelligently we can operate.

“Make in India” is more than a slogan. It’s a call to embrace digital intelligence — to produce brighter, cleaner, and faster than ever before.

And ERP is the backbone that makes this vision palpable.

A data-driven ERP doesn’t just reorganise operations; it makes a culture of visibility and accountability.

It boosts teams to look at the same data, pursue the same goals, and measure success transparently.

In global markets where excellence, speed, and agility decide the winner, this kind of digital support becomes the biggest competitive advantage Indian constructors can have.

Conclusion

Robots don’t define the factories of the future — they’re defined by real-time intelligence.

Manufacturers that move from elementary automation to data-driven ERP systems will not only recover efficiency, but also future-proof themselves against indecision.

Whether it’s envisaging demand shifts, dropping waste, improving cash flow, or intensifying globally, ERP turns everyday data into tactical power.

For Indian manufacturers equipped to play on the world stage, this isn’t just a technology promotion.

It’s a conversion of mindset — from reacting to get ahead, from information excess to insight-driven growth.

If your business is ready to take that jump, it’s time to discover how a tailored SAP or ERP solution can help you turn operational data into your most valuable asset.