SAP Manufacturing

- Highbar Technocrat

- Blogs

- December 26, 2025

Connect With Us

Walk into any modern manufacturing plant today, and you’ll notice a strange contrast.

The shop floor looks sharp, automated, and efficient. Machines hum with precision, screens glow with dashboards, and teams move with a sense of purpose.

Yet behind this high-tech surface, the same old problems keep returning — machines fail without warning, production slows down unexpectedly, materials don’t arrive when they should, and decisions get delayed simply because the data isn’t complete.

This is the truth many manufacturers quietly acknowledge:

Automation alone can’t fix the complexity of modern manufacturing.

A factory can be busy without being intelligent.

It can be automated without being predictive.

And that’s why the real transformation starts when AI steps into the ERP ecosystem.

This is the moment the industry shifts:

– from reacting to disruptions… to anticipating them,

– from watching dashboards… to receiving insights,

– from depending solely on experience… to enhancing it with live intelligence.

For Indian manufacturers competing in a global market, this isn’t just another technological upgrade.

It’s a defining transition — the point where operations gain foresight instead of hindsight.

Pain Points Manufacturers Deal With Today

Even with advanced machines and talented people, most factories still feel a step behind what the market demands.

1. Unplanned Downtime Disrupts Everything

Machines fail without warning.

When that happens, schedules collapse, workers wait, and orders get pushed.

Every hour of downtime is expensive — financially and reputationally.

2. Supply Chain Uncertainty Keeps Operations on Edge

Material delays, random suppliers, and changing lead times make planning stressful.

When one link weakens, the entire chain feels it.

3. Too Much Data, Too Little Insight

Manufacturers collect huge amounts of data… but very few teams can interpret it fast enough.

Information stays stuck in silos — production has one version, finance another, procurement another.

4. Forecasting Still Feels Like Guesswork

Demand shifts quickly.

Customer expectations change overnight.

Trying to predict it manually feels like operating blindfolded.

5. Compliance and Reporting Add Hidden Workload

Standards tighten every year.

Documentation grows thicker.

Teams spend more time tracking paperwork instead of improving productivity.

All these problems share one root cause:

Manufacturers can see what already happened — but rarely what will happen next.

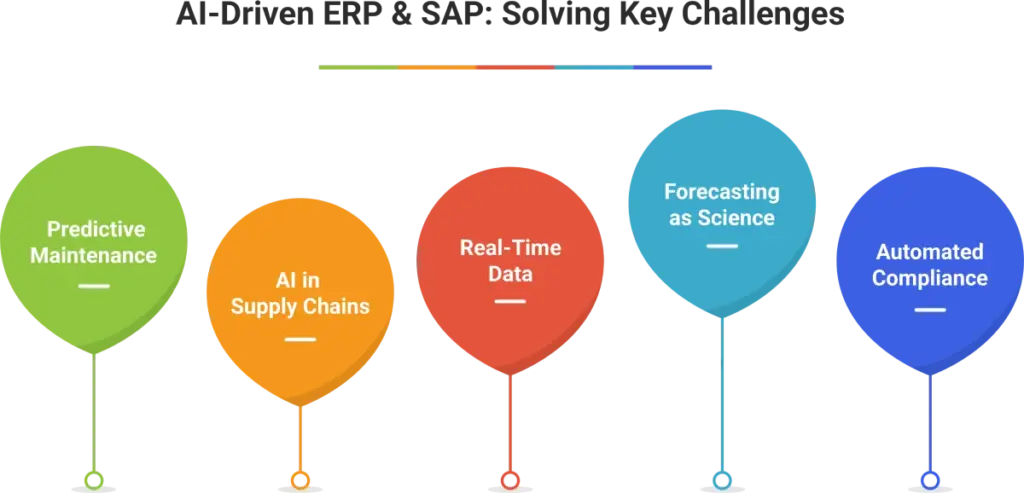

How AI-Driven ERP and SAP Systems Solve These Challenges

When AI integrates with ERP, the factory doesn’t just become digital — it becomes predictive.

The system doesn’t wait for mistakes or breakdowns; it signals them before they occur.

Here’s how:

1. Predictive Maintenance Removes Surprises

Predictive maintenance removes surprises, which is a pretty good reason for making it one of the most important applications of AI in the industrial sector.

AI keeps an eye on the machine’s behaviour, usage patterns, and early warning signals.

The AI model is aware of when the machine is most likely to operate inefficiently, become overheated, or break down completely.

Maintenance teams, instead of waiting for the breakdowns, get the matters addressed early on thus limiting the overall disruption.

This eventually results in a manufacturing unit that always outsmarts the unplanned downtimes.

The second advantage of AI is the supply chain visualization.

2. AI in Supply Chains

Modern ERP systems take into consideration various factors like the reliability of supplier, logistics patterns, and material movement for their analysis.

The system highlights the delay instantly, if it is likely, allowing the teams to re-route the plans or alter the scheduling.

No more last-minute wonders.

- No more panic orders.

- Just cleaner, smoother planning.

3. Real-Time Data Becomes Useful, Not Overwhelming

With AI-driven ERP, divisions no longer work in discrete silos.

Everyone sees the parallel live data — production, finance, HR, procurement.

This shared discernibility leads to faster decisions and rarer misalignments.

In its place of waiting for weekly reports, leaders performance in the moment.

4. Forecasting Becomes a Science, Not Guesswork

AI studies trends, market behaviours, seasonal demands, and past patterns.

It creates demand forecasts with far greater accuracy than any manual method.

Manufacturers finally get answers to questions like:

- What will customers need next month?

- How much should we produce?

- Which product lines will grow?

This reduces overproduction and underproduction — improving both efficiency and cash flow.

5. Automated Compliance Saves Time and Stress

AI-enabled ERP tracks every process automatically.

Audit trails are generated in the background.

Quality checks align with regulations.

Instead of chasing for documents or rushing before reviews, compliance becomes a natural part of daily procedures.

Why AI + ERP Matters for Indian Manufacturing

India is moving toward becoming a worldwide manufacturing powerhouse.

But to achieve that, factories must become not just automated… but intelligent.

AI-driven ERP brings three major advantages:

1. Confidence in Every Decision

Leaders no longer rely on gut feeling.

They make choices backed by real-time, predictive insights.

2. Stability in a Volatile Market

When the unforeseen happens — raw material shortage, demand fluctuation, regulatory changes — AI gives plants the agility to reply fast.

3. Scalability Without Losing Control

As manufacturers grow through states or countries, ERP ensures the entire ecosystem stays connected, transparent, and manageable.

In essence:

ERP makes manufacturing efficient.

AI makes manufacturing unstoppable.

Together, they generate the kind of intelligence Indian companies need to compete globally.

Conclusion

Manufacturing is shifting faster than ever — and companies that depend on only on traditional systems will struggle to keep pace.

The future fits to factories that can predict, not just produce.

Where machines are monitored intelligently, decisions are made instantly, and risks are managed before they appear.

This is exactly what AI-powered ERP and SAP systems deliver.

Not just automation — anticipation.

Not just data — direction.

If your establishment is ready to move from responsive operations to predictive excellence, the time to explore AI-driven ERP is now.

It’s not a trend.

It’s the new foundation of competitive manufacturing.