SAP Manufacturing

- Highbar Technocrat

- Blogs

- December 25, 2025

Connect With Us

Over the last two years, businesses worldwide have experienced supply chain interruptions on a scale never previously intended. Raw material shortages along with transport congestion, dramatically changing consumer preferences and political tensions all contribute to disruptions that have become a new normal. In these situations, organizational stability and efficiency are greatly reliant on the velocity of the response to the change that the organization is able to effect.

Speed and swiftness of response are the main reasons, as well as the one and only factor, that the availability of data in real-time has become a major concern at the strategic level of manufacturing in the modern era. Manufacturers that are still depend on on fragmented tools, manual updates, or old reporting cannot manage with breaks fast enough to remain in the game.

To bridge this gap, the majority of innovative manufacturers are adopting SAP manufacturing solutions. With integrated information and real-time analysis behind them, SAP Manufacturing software connects the entire supply chain from production and procurement to warehousing and fulfilment in a way that allows decisions to be made from real-time, current data.

The Problem: The Old Supply Chains Aren’t Designed to Deal with Disruption

Traditionally, supply chains were planned for stability and predictability. Long scheduling horizons, stable supplier bases, and sensibly reliable demand forecasts were the order of the day. But the manufacturing certainty of today is:

- Highly dynamic

- Digitally enabled

- Customer-centrical

- In height on customization

- Home to global supplier networks

So, conventional, reactive planning is no longer enough.

Even a slight delay in raw material accessibility can lead to:

- Production go-slows

- Extreme overtime cost

Slowed delivery schedules - Improved logistics cost

- Loss of customer trust

The only way to traverse this type of complexity is real-time visibility and harmonized activities—and that’s where SAP manufacturing enters the picture.

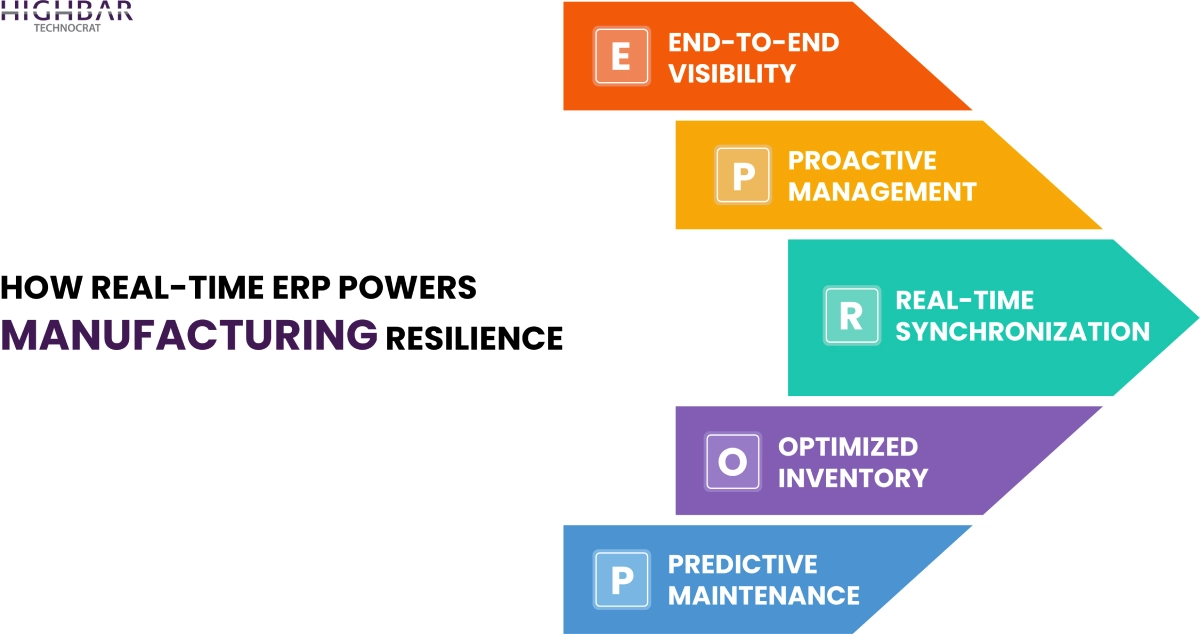

How Real-Time ERP Visibility Empowers Manufacturers to Stay Resilient

1. Single Source of Truth for End-to-End Visibility

One of the greatest advantages of SAP Manufacturing software is that it brings together all manufacturing operations in a single digital landscape. Instead of running as silos, departments are given one, common, real-time picture of things.

With data at its centre, inventers get to see things follow right away:

- Material position on incoming shipments

- Inventory by storage places

- Production status by machine and line

- Work order priority

- Supplier delivery consistency

- Customer order schedules

This 360-degree slide moves the blind spots sideways, empowering proactive decision-making.

2. Proactive Supplier and Procurement Management

Supply chain disturbances in most examples start outside of the plant—between vendors and logistics companies. SAP manufacturing solutions cover supplier monotonous analytics that help procurement teams with:

- Monitoring delivery accurateness and lead time inclinations

- Identifying challenging suppliers early

- Compare multiple vendor options in real time

- Notify automatically when delivery commitments change

Fortified with this information, organizers are better able to negotiate, avoid dependence on weaker suppliers, and acquire alternates in a hurry.

3. Demand and Production Synchronization in Real Time

Demand changes can interrupt production planning if done based on out-of-date data. SAP manufacturing software operates real-time demand signals to make dynamic adjustments to:

- Production run order systems

- Material distribution

- Labour and equipment development

- Levels of stocking finished goods

This maintains production capacity in line with true demand, preventing overproduction or stockouts.

The result is lower response time and improved production process.

4. Inventory and Warehouse Optimization

Stockout or surplus account can either block reserves in surplus stock or standstill production due to lack of material. SAP Manufacturing software develops:

- Computerized stock level monitoring

- Real-time warehouse discernibility

- Intelligent reorder points

- Batch and serial number traceability

This allows manufacturers to enjoy timely availability of materials and reduces carrying and storage cost.

5. Predictive Maintenance for Equipment Reliability

No production downtime is suitable if supply chains are volatile. SAP manufacturing powers device data, IoT feeds, and analytical analytics to:

- Track machine condition in real time

- Detect irregularities early

- Automate maintenance schedules

- Lower unplanned interruption

This certifies production is always flowing smoothly even when supply chains are getting stressed.

Real Business Impact: Turning Disruptions into Competitive Benefit

Manufacturers who use SAP manufacturing solutions reliably report:

- Business Area\measurable Improvement

- Manufacture Competence\t+20% to +40%

- Inventory Cost Reduction\t10% to 25%

Supplier Risk Exposure\reduced by 30%

- Order Fulfilment Accuracy\t Up to 98% consistency

- Machine Stoppage\reduced by 15% to 35%

Gains such as these do more than protect operations through disruptions—they promote competitiveness long term.

Example Scenario

One manufacturer of industrial components suffered with recurring interruptions from variable delivery of raw materials from overseas. Production squads learned too late about scarcities—hence, frantic purchases at high prices.

After SAP integration:

- Material availability notifications were triggered days in advance

- Supplier performance dashboards highlighted weak spots

- Alternate supplier recommendations were automated

- Production schedules were accustomed ahead of time

The company reduced emergency procurement costs by 22% and enhanced on-time delivery to 94% from 76% over a year.

Conclusion: Resilient Manufacturing Starts with Real-Time Visibility

In today’s unbalanced world, the strongest manufacturers remain those with the largest resources—but the ones with the greatest visibility and fastest response capability.

SAP manufacturing helps organizations prepare ahead of time for disruptions, react rapidly and decisively, and remain stable when the marketplace is volatile. With SAP Manufacturing software, manufacturers are not only receiving workflow automation—they’re also getting the quickness, intelligence, and flexibility they must have to thrive in today’s supply chain environment.

Disruptions will never disappear.

But with real-time ERP visibility, you are in control—not the disruption.