SAP Manufacturing

- Highbar Technocrat

- Blogs

- December 26, 2025

Connect With Us

In the recent world of manufacturing, a rare minute of unforeseen downtime can make all the difference between meeting a deadline and losing a huge client.

Each machine, each procedure, and every minute matters. Manufacturers no longer have time to wait for equipment failure before acting.

And that is where predictive maintenance with the support of a robust ERP system comes in – it’s a game-changer.

For more than a decade now, Highbar Technocrat, a top SAP and ERP solutions provider in India, has enabled manufacturing behemoths to revolutionise the manner in which they operate.

Having a presence in 70–80% of India’s manufacturing base, Highbar is allowing manufacturers to anticipate issues before they arise—and that’s redefining what it actually means for an organisation to have operational excellence.

From Reactive to Predictive: The Shift Manufacturers Needed

Old-style maintenance systems were reactive—equipment was fixed only after it failed. That may have been good enough decades ago, but it’s no longer possible in an era of precision, speed, and competition.

Downtime currently translates to idle production lines, delayed shipments, and upset customers.

The new manufacturing environment needs more than mere upkeep. It requires smart insight—sensing when a component may fail and repairing it before it does.

That’s the potential of predictive maintenance, and when paired with an end-to-end integrated ERP system such as SAP Manufacturing software, it is an all-encompassing intelligence loop between machines, people, and business decisions.

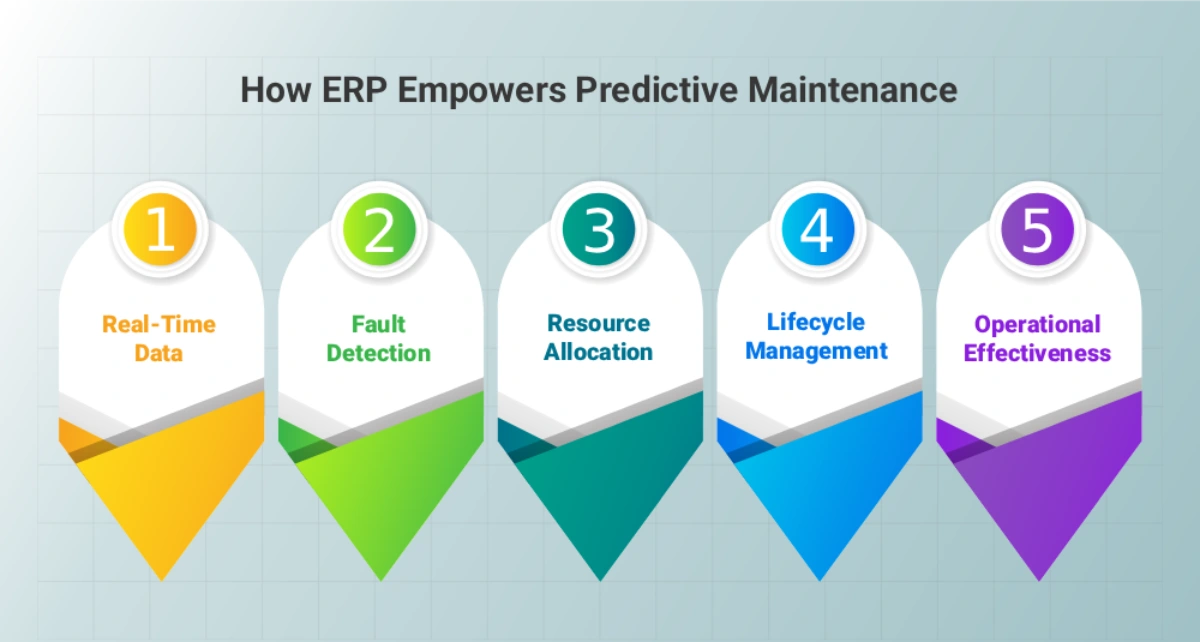

How ERP Empowers Predictive Maintenance

A powerful ERP solution such as SAP Manufacturing serves as the plant’s digital nervous system. It links shop-floor information to decisions made on the top floor, opening a dynamic feedback cycle that drives better, quicker decision-making.

Here's how ERP fuels predictive keep in manufacturing:

1. Real-Time Data Collection and Integration

New machines have sensors fitted, which collect data endlessly—temperature, vibration, speed, pressure, and so on. The ERP system aggregates all that data into one place, as long as engineers and decision-makers have real-time data about machine health.

2. Fault Detection in Early Stages through Analytics

ERP software such as SAP Manufacturing software leverages sophisticated analytics and AI algorithms to identify anomalies. As a pattern suggests a possible failure, the system creates alerts or service orders long prior to the breakdown occurring.

3. Intelligent Planning and Resource Allocation

Predictive maintenance works only if it’s timely. ERP supports planning maintenance operations so that they can minimise the disruption to production. It also coordinates the accessibility of the correct parts, technicians, and tools, lessening downtime.

4. Enhanced Asset Lifecycle Management

Every single maintenance operation is recognised and monitored in the ERP system. This creates a digital record of each machine over time, allowing managers to plan substitutes, upgrades, and investments with data-based conviction.

5. Cost Savings and Operational Effectiveness

ERP-driven predictive maintenance reduces emergency repairs, overtime expenses, and impromptu downtime. It changes the paradigm from “firefighting” to “strategic maintenance” so that companies are able to achieve more output from their existing assets.

The Human Impact: More Than Just Machines

At the centre of each factory are individuals—engineers, technicians, and operators who bring the manufacturing process to life. Predictive maintenance enabled by ERP doesn’t substitute them; it augments them.

When automation and integration take place, the human resources focus on innovation instead of intervention. Technicians no longer spend their time troubleshooting the same things every day; they’re instead reviewing insights, strategising for improvement, and optimising production quality.

This synergy of human and digital intelligence is the “smart synergy”—future-proof manufacturing thinking, which Highbar Technocrat refers to.

An Example from Reality: Predictive Maintenance in Action

Consider a big car manufacturer employing Highbar’s SAP Manufacturing ERP in several plants. Formerly, the maintenance squad would wait for motors or hydraulic pumps to break down, resulting in days of lost production.

Now that predictive analytics are combined into their ERP system:

- Sensors continuously monitor machine health.

- The ERP system forecasts when a motor or bearing may fail through temperature and vibration inputs.

- Automated maintenance orders are scheduled and written off-peak.

- Pre-scheduled spare parts are ordered ahead of time.

The outcome?

- 60% decrease in unplanned downtime

- 25% improvement in machine availability

- Substantial cost savings in maintenance

- This is not efficiency—it’s transformation.

- Predictive Maintenance: The Competitive Edge

In today’s globalised economy, where speed and reliability are the competitive battlegrounds for manufacturers, predictive maintenance via ERP is turning into a strategic differentiator. It’s not anymore about correcting issues; it’s about avoiding losses ahead of time.

Highbar SAP Manufacturing customers have cited:

- Improved visibility of operations

- Increased decision-making speeds

- Decreased maintenance expenditures

- Improved product quality

- Better agreement and safety standards

When far-sightedness insights seamlessly change from the top floor to the shop floor, manufacturing organisations become stronger, more responsive, and profitable.

Highbar Technocrat: Accelerating the Next Generation of Manufacturing

With Highbar Technocrat as one of India’s leading ERP and SAP solution providers, industries like manufacturing, construction, real estate, and infrastructure have been digitised.

Highbar Technocrat’s solutions are crafted to close the loop between operational requirements and technology superiority.

For industrial manufacturing businesses, High Bar's ERP deployments provide:

- Horizontal connectivity to IoT and automation platforms

- Predictive analytics for proactive upkeep

- Cloud-based scalability for growth

- Custom dashboards to inform data-driven decisions

Through the integration of all layers of operations—raw materials to finished goods, shop floor to boardroom—High bar allows manufacturers to run confidently, clearly, and in control.

Conclusion: The Future Runs Predictively

Predictive care through ERP isn’t a trend; it’s the foundation of modern manufacturing. It’s about giving machines a voice, listening to what they say, and intervening before it’s too late.

With leaders like High bar Technocrat at the lead, Indian manufacturers are not just catching up—they’re setting new global standards in operational excellence.

In the future, interruption will not be a believed expense—it’ll be an unnecessary incident. And predictive maintenance with SAP Manufacturing software will make that a reality.